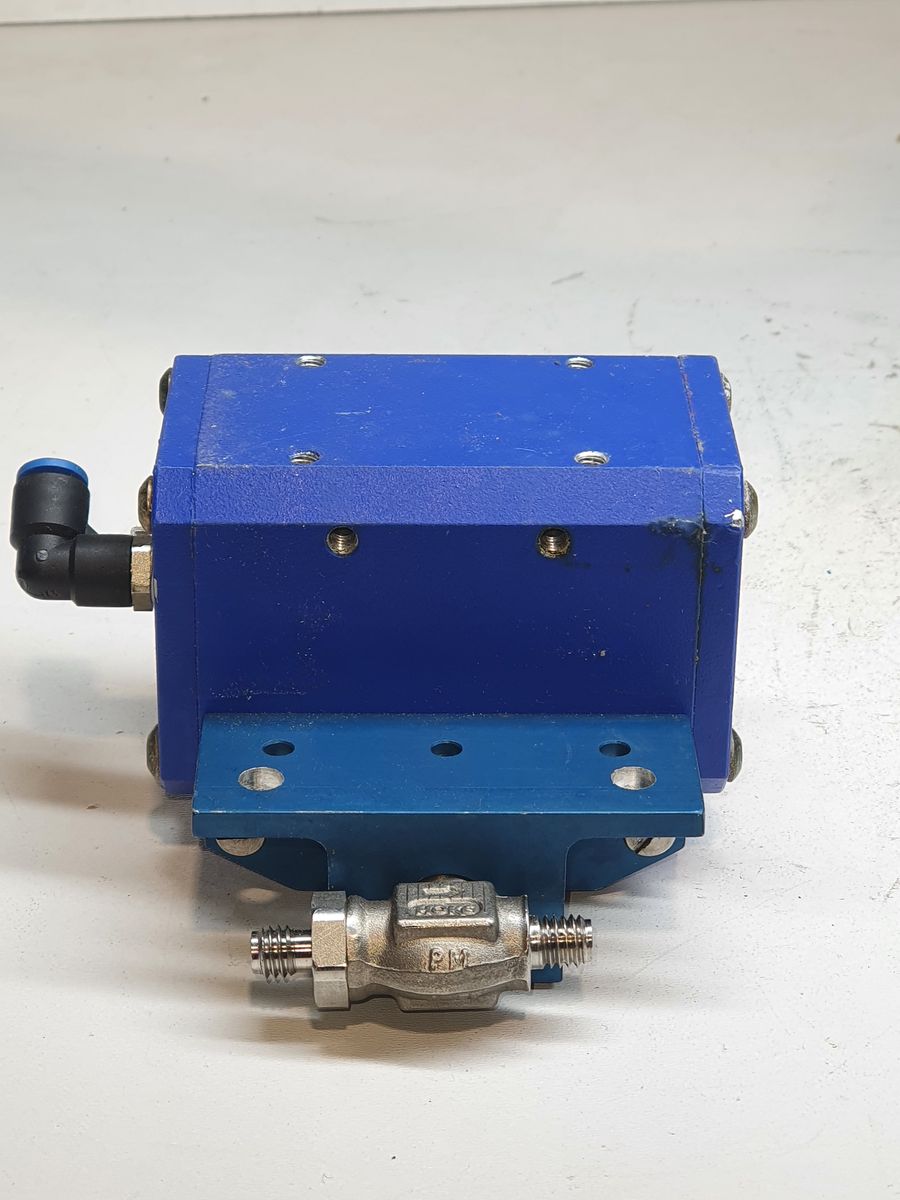

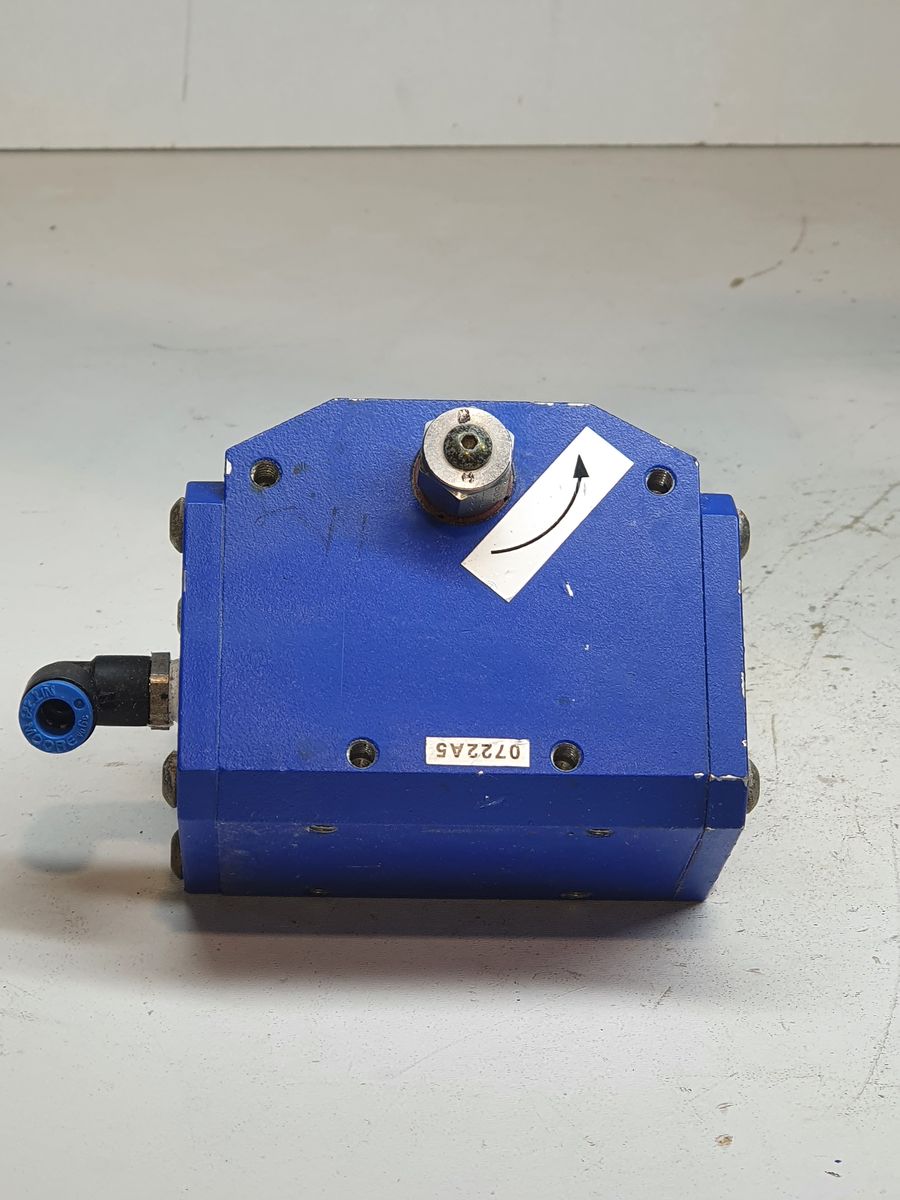

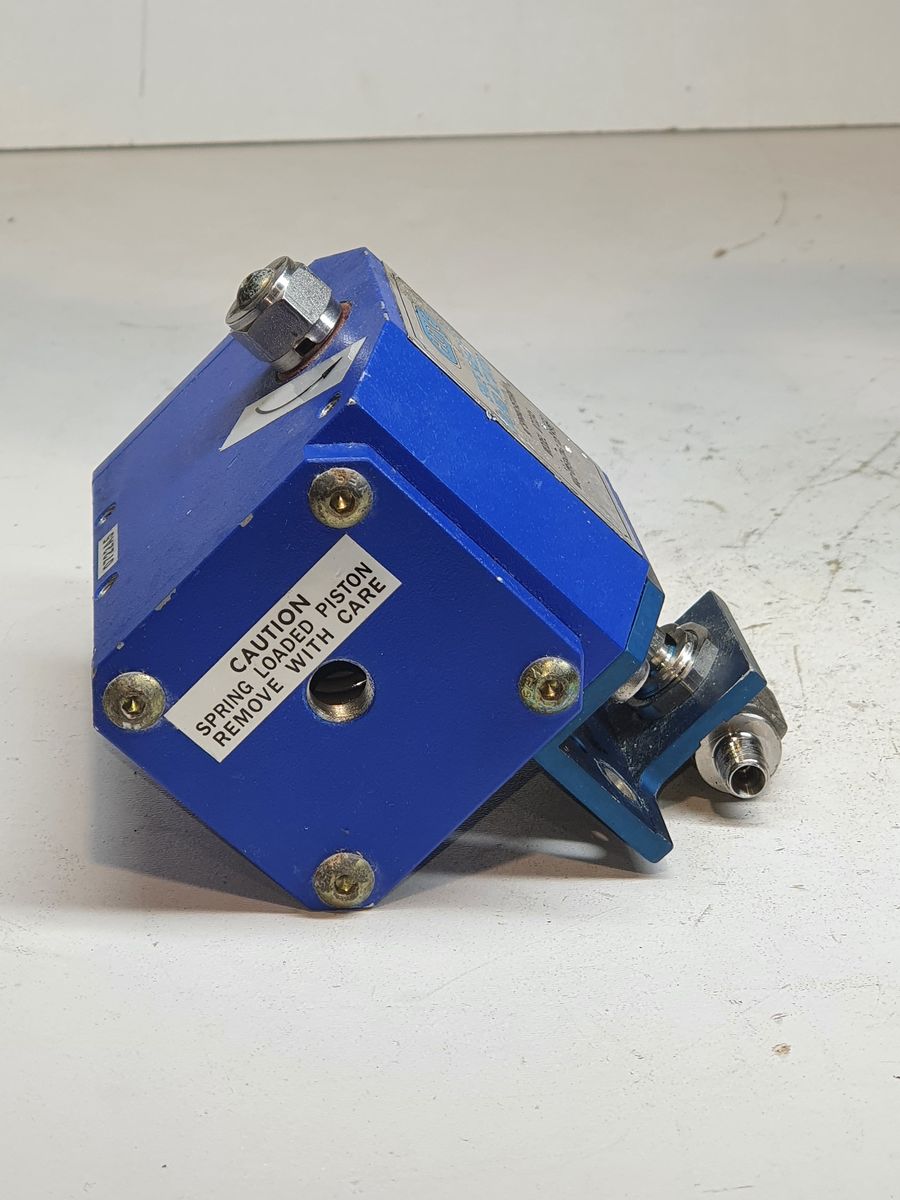

Hoke 0722A5/ 7142G2Y

Garancia Információk

Hoke 0722A5

|

Specification |

Value |

|---|---|

|

Housing Material |

Polyurethane coated aluminum |

|

Maximum Operating Pressure |

125 psig (9 bar) |

|

Air Supply Connection* |

1/8 Female NPT |

|

Operating Temperature Range A4 Actuators |

0° to 250° F (-18° to 121° C) |

|

Operating Temperature Range A5 Actuators |

0° to 400° F (-18° to 204° C) |

|

Cycle time** |

1 second (dependent on air supply) |

|

Cycle Life |

250,000 cycles minimum |

|

Weight |

1.7 lbs. (0.75 kg) |

Hoke 7142G2Y

|

Connections - Inlet |

1/8" Gyrolok |

||

|

Connections - Outlet |

1/8" Gyrolok |

||

|

Body Material |

316 Stainless Steel |

||

|

Operating Pressure Range |

1500 psig at 70° F (103 bar at 21° C) |

||

|

Operating Temperature Range |

-40 to +350 ºF-40 to +176 ºC |

||

|

Orifice |

0.093 in2.40 mm |

||

|

Cv |

0.23 |

||

|

C |

1 9/32 in33.0 mm |

||

|

E |

2 19/32 in66 mm |

||

|

H |

13/32 in10 mm |

||

|

H1 |

11/32 in9 mm |

||

|

Panel Hole |

19/32 in15 mm |

||

|

Panel Thickness |

3/16 in5 mm |

||

|

Features & Benefits |

|